Why This Matters Now

Environmental and energy regulations are accelerating—local building codes, sustainability incentives, and ESG demands are pushing finishes, roofing, and material selections in new directions. For contractors and subcontractors, the shift isn’t just about being green—it’s about staying competitive, compliant, and risk‑resilient.

But to bid well in this landscape, your estimates must fully account for both material cost premiums and compliance burdens. That’s where expert estimating like what Pinnacle provides becomes a strategic differentiator.

Green Drywall & Finishes: More Than Just Buzzwords

Modern drywall and finishing materials are evolving rapidly:

- Moisture‑ and mold‑resistant gypsum panels: These use treated cores and paper facings to inhibit mold growth—ideal for humid or indoor environments. USG’s Mold Tough line is a widely adopted example. USG

- Recycled-content panels: Some boards now incorporate post-industrial gypsum or recycled paper fibers, helping projects qualify for green certifications such as LEED. americangypsum.com

- Low-VOC and antimicrobial paints: Paint manufacturers are offering formulas that reduce indoor emissions and microbial growth—an increasingly common spec in institutional and occupied spaces.

- Finish upgrades for IRS & health codes: Especially in healthcare, education, and public buildings, specifying antimicrobial finishes or sanitized surfaces may be mandated or strongly preferred.

Estimator Tip: For these finishes, estimating the incremental cost delta (versus standard materials) and including the labor complexity (handling specialty panels, additional prep) is crucial.

Flooring & Countertops: The Sustainability Turn

Finishes now carry both aesthetic and environmental weight:

- Eco-friendly flooring: Trends lean toward bamboo, cork, recycled rubber tiles, and bio-composite terrazzo—a rising select in sustainable interiors.

- Recycled stone & glass countertops: Suppliers now produce slab products combining recycled glass, mirror fragments, and cement matrices, offering the appeal of stone with lower embodied carbon.

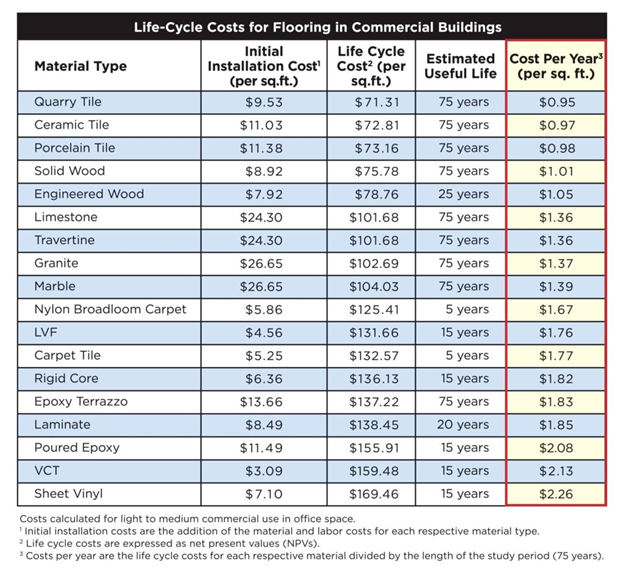

- Lifecycle cost modeling: Estimators should incorporate not just initial install costs, but maintenance, replacement cycle, and end-of-life disposal or recycling.

Comparative Life-Cycle Costs of Flooring Materials in Commercial Buildings

“Cost per Square Foot Over Time Across Common Commercial Flooring Options”

Roofing & Energy Codes: “Cool Roofs” Are Here to Stay

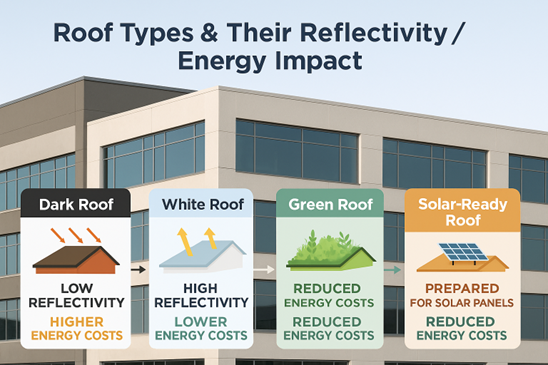

Roofing is a frontline battleground in sustainability codes:

- Cool roofs use reflective surfaces (white membranes, high-albedo coatings) to reduce solar heat absorption. According to DOE, conventional dark roofs may reach 150 °F, while a reflective roof can stay more than 50 °F cooler in peak sun conditions. The Department of Energy’s Energy.gov

- Energy savings: Cool roofs can cut cooling loads by up to 15% for single-story buildings. EESI

- Regional variance: In hot climates, savings may be higher; in cold climates, heating penalties must be weighed. Some studies show annual energy reductions ranging from 15% to 35.7% depending on location and roof design. ScienceDirect+1

- Incentives & codes: Many municipalities now require or incentivize roofs with high solar reflectance. Some utilities offer rebates or link roofing to green building credits.

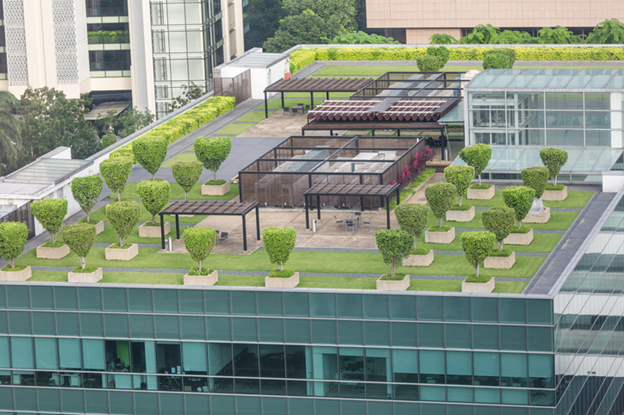

- Green roofs & urban cooling: Beyond reflectivity, vegetated “green roofs” reduce ambient urban temperatures, promote stormwater management, and can improve insulation. US EPA+1

Estimator Note: When bidding roofing scopes now, account for:

- Premium cost for reflective membranes or coatings

- Enhanced substrate or insulation to support reflective surfaces

- Compliance reviews, testing, and energy modeling support

- Trade coordination (HVAC ducting, rooftop equipment interfaces)

How Estimators Stay Ahead: What Pinnacle Does Differently

With so many evolving product types and codes, contractors can’t rely on static unit books and assumptions. Here’s how Pinnacle Estimating Services ensures accuracy in this changing environment:

| Challenge | Our Approach |

| Rapid product evolution | We maintain a dynamic product database updated with manufacturer spec sheets, reflectance values, VOC ratings, and regional versions |

| Local code variability | Our estimators monitor jurisdictional code changes (e.g. cool-roof mandates, finish emissions limits) to ensure compliance |

| Premium and compliance cost capture | We build deltas into takeoffs—estimating margin for the “green premium” plus compliance verification |

| Lifecycle and energy modeling | For large projects, we run high-level energy or lifecycle cost comparisons (when required by clients) |

| Client education & alternative scenarios | We provide variant estimates (standard vs premium green) so clients can see tradeoffs |

When your bid includes sustainable or code-driven materials, you want a partner who not only knows the numbers—but knows the future. That’s what Pinnacle delivers.

Suggested Visuals & Data Inserts

- Bar chart: Comparative embodied carbon of drywall / flooring / roofing material choices

- Line chart: Cooling savings (%) vs. roof reflectance

- Infographic: Summary of emerging code mandates by U.S. regions (e.g. cool-roof required in AZ, CA, FL)

- Project photography: Real installations of reflective roofs, recycled-glass countertops, or sustainable finish interiors

Final Thought: Green Isn’t Optional—It’s Strategic

Sustainability is no longer a niche bid-item—it’s increasingly baked into codes, owner requirements, and energy incentives. Contractors and subs who neglect it risk losing bids, failing compliance, or absorbing hidden costs.

By partnering with Pinnacle Estimating Services, you get more than quantities—you get future-aware estimates that anticipate the premiums, efficiency impacts, and compliance burdens of green finishes and roofing scopes. In 2025 and beyond, that difference separates winning bids from margin damage.

Let’s build smarter and more sustainably—together!